Corrosion and wear limit the period of use of plants and machines. The use of ceramic components and coatings specially developed to prevent this happening can help to extend the period of operation, thus shortening repair and down times. Intensive research and development have provided us with materials with top wear resistance qualities.

Besides components made of the ceramic materials alumina, silicon carbide and nitride-bonded silicon carbide, also hard metals, composites and Cermets as well as coatings (flame-spraying, vacuum plasma and high-speed plasma spraying) from various ceramics, metals with hard material mixtures are used. According to requirements, the products can be provided with intermediate or adhesive layers.

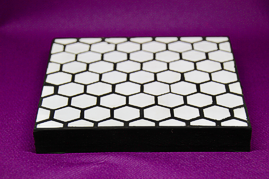

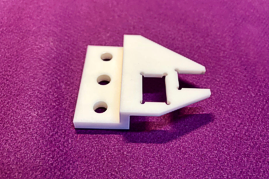

Individual mosaics and mats produced out of them are standard components, either on paper/foil or rubber, tiles, solid and hollow cylinders or tubes, segments, bend segments, form pieces and cones.

The ceramics are either cemented on, vulcanised on or welded on. For use in the food industry there are ceramics or hard metals available with the corresponding food licensing (FDA licensing).

Besides the use of ceramics, in some cases fused cast basalt, fused cast corundum, chromium white cast iron, and hard face welding, as well as wear-resistant concrete are employed.

|

|

|

More information & news